I decided that the silver triple trees and handlebar risers were just too out of place with the direction my bike has gone. And, since I have a bunch of time on my hands waiting for China to fix their screw up and for the snow to melt, I decided to tear the front end off and paint them black. Turned out great.

Friday, February 7, 2014

Painted Triple Trees

I decided that the silver triple trees and handlebar risers were just too out of place with the direction my bike has gone. And, since I have a bunch of time on my hands waiting for China to fix their screw up and for the snow to melt, I decided to tear the front end off and paint them black. Turned out great.

China blows. New Reservoir.

I finally got around to changing out my brake and clutch reservoirs to something more aesthetically pleasing. I turned to China for some cheap, simple, black reservoirs. Of course... they send me one black and one gold. One of those moments where you think, "You had one job!"

So now I get to wait weeks and weeks for them to get their shit together and send me a new one.

Here's some previous shots as well as the one that I got installed:

So now I get to wait weeks and weeks for them to get their shit together and send me a new one.

Here's some previous shots as well as the one that I got installed:

Wednesday, January 29, 2014

Homemade Fork Spring Compressor

The last tool I made was just a "U" of flimsy steel, didn't hold up very long and was hard to work with. I happened to look inside one of the scrap steel bins at work and saw a 4 inch long piece of pipe. I thought it would be the perfect size for making a new compressing tool. I took it home and threw it in the cutoff saw to take make a 3/4" width ring. I then ground off all the shavings and sharp edges, and threw it in the drill press. My bit couldn't reach the other side of the ring so I took it out of the vise, and marked where the hole on the other side would have to be.

After drilling both holes to the correct tap diameter, I tapped them for the 3/8" bolts that I would be threading into them. Since the bolts meet in the middle, I think it should work just fine, haven't had an opportunity to use it yet. Painted it gloss black and I'm done!

After drilling both holes to the correct tap diameter, I tapped them for the 3/8" bolts that I would be threading into them. Since the bolts meet in the middle, I think it should work just fine, haven't had an opportunity to use it yet. Painted it gloss black and I'm done!

Friday, January 24, 2014

Reassembly Updates

So I finally got all the parts in that I need to repair the damaged timing side of the motor: Idler gear, reduction pin, flywheel gear, and starter clutch. I also decided to just replace the entire side cover so I didn't have to worry about that Bondo'ed retaining lip. A fellow DMF member offered me a screaming price on the cover so it was hard to pass up. All in all, after selling that nice Nichols flywheel that I couldn't use, I came out ridiculously cheap for the parts. All included, I spent $59 on the replacement parts.

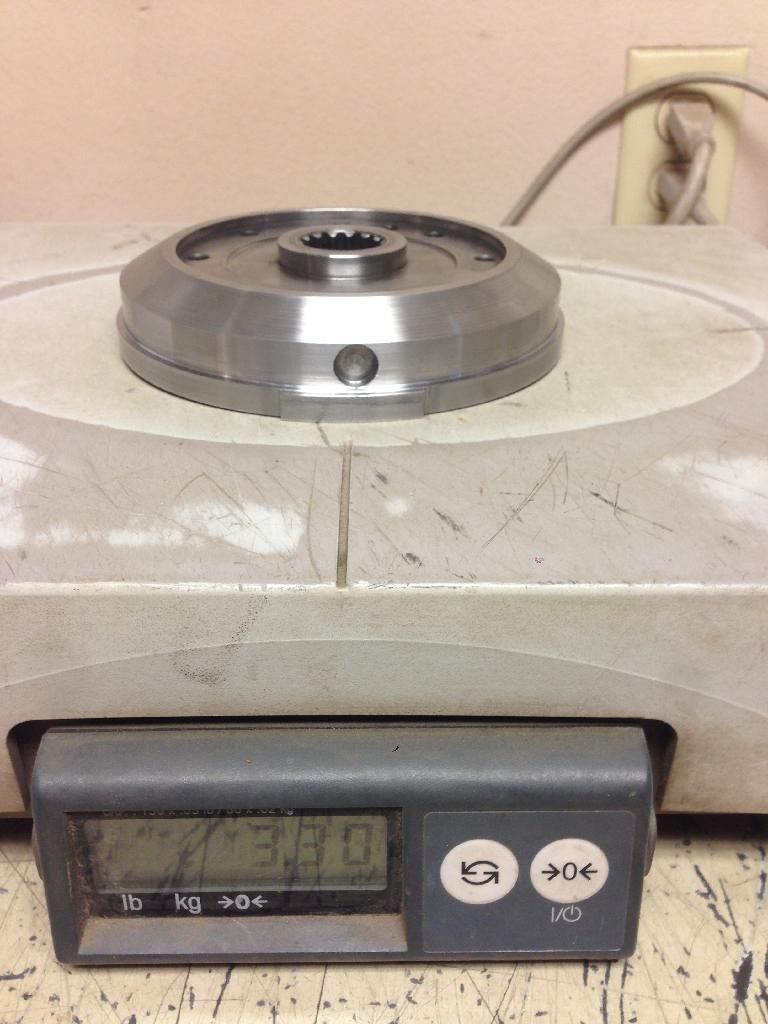

Earl and I took some more material off the flywheel and drilled a balancing hole, shown here:

After getting the new side cover in the mail, I realized I wouldn't be okay with having two side covers of different color, so I decided to prep and paint them. While I was cleaning the clutch-side cover, I ran my index finger along a very sharp lip, and got insta-blood:

Truly blood, sweat, and tears poured into getting this thing ready.

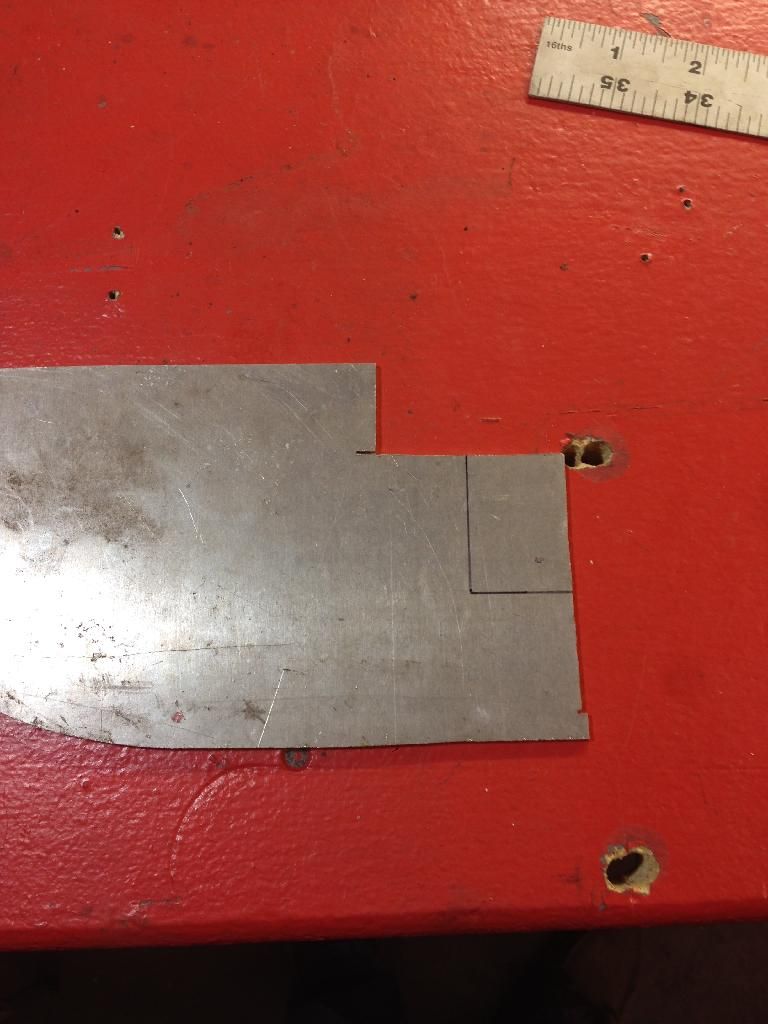

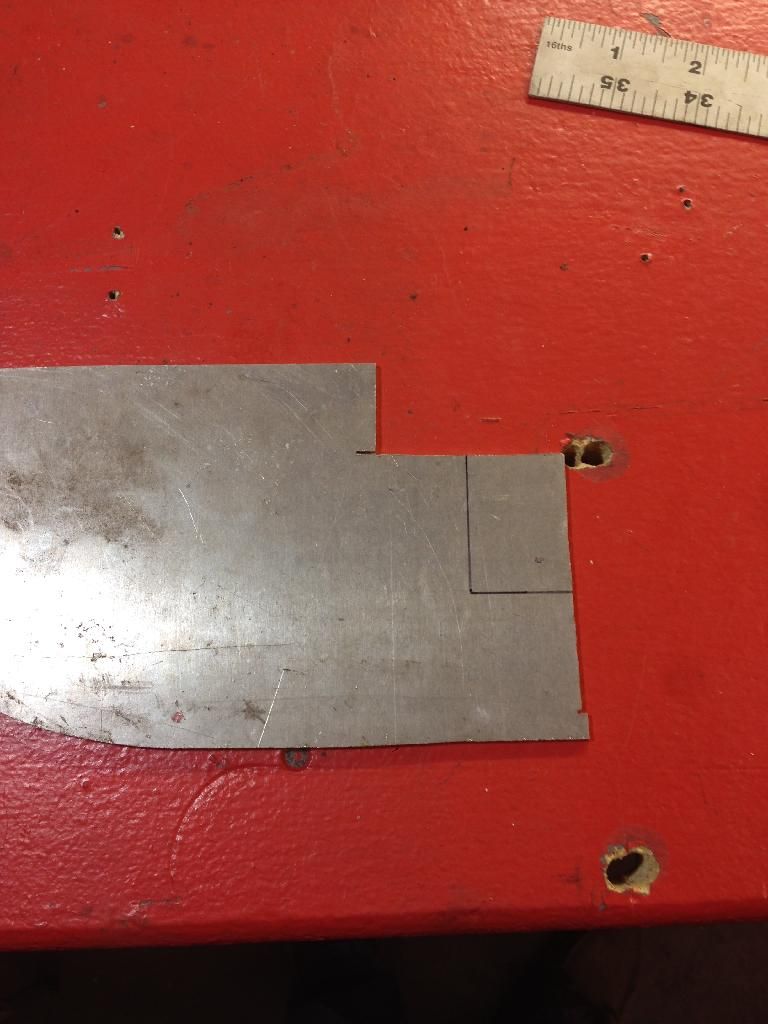

Before I started painting I needed to make a small cover and gasket for a sensor hole in the new cover (my old one didn't have the hole). Started off with a sheet of aluminum, cut out a rectangle, then used my Dremel, grinding wheel, and file to shape the rest of it. A piece was cut out of stock gasket material in the shape of the cover.

Here are the covers before paint, showing why I wanted to paint in the first place:

Here they are after the first, light coat of VHT engine paint. Yes, I used some duct tape for masking tape. I made the mistake of buying Ace Hardware brand painters tape and it was absolutely terrible. Had to make due with what I had at that point:

Three coats in:

After 30 minutes of curing at 200 degrees in the oven... I don't think Laura was too happy about motorcycle parts baking in her kitchen...

Finally a picture on the bike. I'm still waiting on the gasket for the right side cover to come in:

Earl and I took some more material off the flywheel and drilled a balancing hole, shown here:

After getting the new side cover in the mail, I realized I wouldn't be okay with having two side covers of different color, so I decided to prep and paint them. While I was cleaning the clutch-side cover, I ran my index finger along a very sharp lip, and got insta-blood:

Truly blood, sweat, and tears poured into getting this thing ready.

Before I started painting I needed to make a small cover and gasket for a sensor hole in the new cover (my old one didn't have the hole). Started off with a sheet of aluminum, cut out a rectangle, then used my Dremel, grinding wheel, and file to shape the rest of it. A piece was cut out of stock gasket material in the shape of the cover.

Here are the covers before paint, showing why I wanted to paint in the first place:

Here they are after the first, light coat of VHT engine paint. Yes, I used some duct tape for masking tape. I made the mistake of buying Ace Hardware brand painters tape and it was absolutely terrible. Had to make due with what I had at that point:

Three coats in:

After 30 minutes of curing at 200 degrees in the oven... I don't think Laura was too happy about motorcycle parts baking in her kitchen...

Finally a picture on the bike. I'm still waiting on the gasket for the right side cover to come in:

Thursday, January 16, 2014

Big Problems

On Sunday, Illinois weather reached a balmy 42 degrees, making about a 70 degree swing from the week before. So, Scott and I decided we had to go for a ride in the beautiful January weather.

The Duc ran great for about 10 minutes, I was VERY happy with the effects of the lightened flywheel. Nice, snappy throttle response. Scott and I get to a gas station to re-fuel, shut the bike down, try to leave, no go. The starter's trying to spin but nothing will happen.

I immediately suspect the ring that had cracked off on the inside of the cover before, and we get the bike back to my garage on a trailer (luckily we were only 1 mile from my house).

Start tearing into the bike and find that not only is the flywheel reluctant to come off of the shaft, but the idler gear is stuck in place as well.

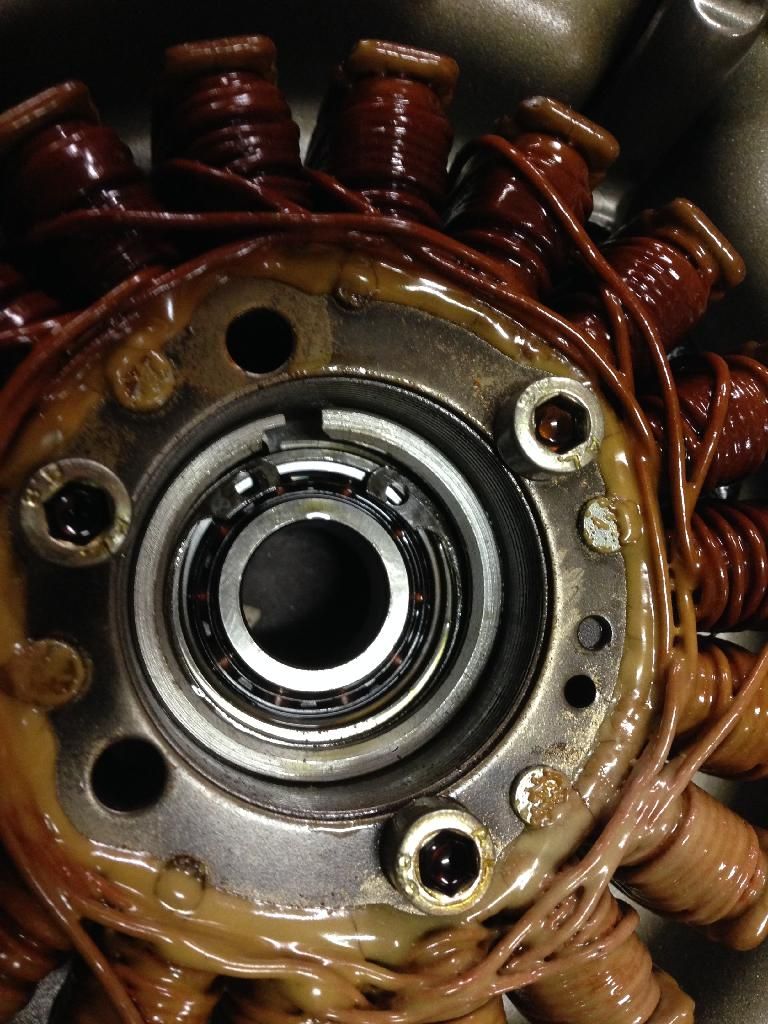

Finally, with a puller, I am able to separate the flywheel from the starter driven gear and find that one of the sprags in the starter clutch is turned 90 degrees:

That sprag turned like that was preventing the "clutch" action and was spinning the gear at the same speed as the flywheel... and motor. Because that gear was spinning it picked up some serious scarring:

Since it was spinning, the idler and starter gears were spinning too. The idler gear only spins on a pin, no bearing, so it must have gotten VERY hot from the friction, then when I shut the motor down it seized itself in place. It took some serious turns on a puller to get the idler gear to come free of the pin:

Now my motor is sitting like this while I wait for parts:

I think there's really only two possible causes of this problem. Either the flywheel is so out of balance it broke the clutch, or the clutch got damaged/installed wrong while I had it out to lighten the flywheel. Either way, I'm going to make sure the flywheel is balanced, and a new sprag is on it's way so the problem should be resolved.

My next issue is that the idler reduction pin is stuck in the case. It has some minor marring on the end of it, which makes me want to remove and replace. However, it's really really stuck. So, I'm halfway considering just lightly sanding it until it's smooth again. Theoretically the idler gear only spins for a short while, and doesn't ever get all that hot. Still deliberating.

Keihin Carbs

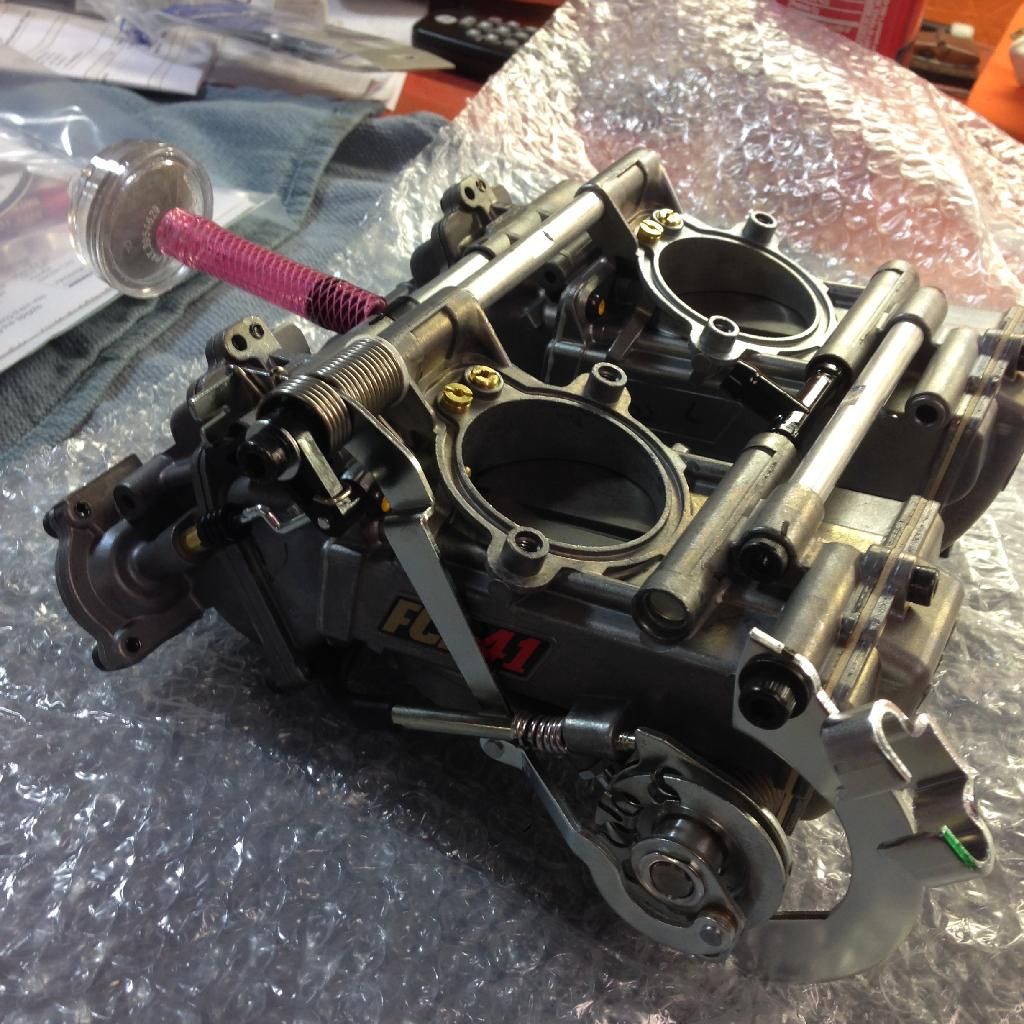

The mailman made me happy yesterday, when I received my brand-new Keihin FCR 41's from Ca-Cycleworks. These bad boys are one of the final pieces I think I'll be able to justify doing to the Monster, aside from suspension upgrades.

As far as installation goes, it was mostly fine. I think for $900+ there are three things that should be included in the kit you receive:

1) New rubber flanges for the air box. The OEM ones are a pain to stretch over the FCR's, AND I had to go to the hardware store to buy longer bolts to allow the clamps to reach all the way around the carb opening.

2) A ball-end 5mm allen key. In the instructions they say you need one. I have non-ball type keys and really didn't feel like buying the ball-end just for the four small bolts you have to use it on. So I ended up grinding one of mine down and doing it that way. Motion Pro includes a hex key in their throttle tube kit. Cycleworks should either include a small, cheap key, or just install the spigots while they're jetting the carbs.

3) Better instructions with some pictures and/or a better drawing than the one that's included. The instructions in the kit did include all the steps necessary for the install, but just weren't that great. For $900+, when you're telling me I need to cut out the vertical support in the air box, I'd like a picture highlighting exactly what I should be cutting out.

Beside that, everything else was positive. The only thing that really sucks is that I CAN'T RIDE RIGHT NOW! It's 12 degrees outside today and the whole left side of my motor is torn apart.

I was real glad I had Alex there to help, I would have needed to be an Octopus if he wasn't there.

As far as installation goes, it was mostly fine. I think for $900+ there are three things that should be included in the kit you receive:

1) New rubber flanges for the air box. The OEM ones are a pain to stretch over the FCR's, AND I had to go to the hardware store to buy longer bolts to allow the clamps to reach all the way around the carb opening.

2) A ball-end 5mm allen key. In the instructions they say you need one. I have non-ball type keys and really didn't feel like buying the ball-end just for the four small bolts you have to use it on. So I ended up grinding one of mine down and doing it that way. Motion Pro includes a hex key in their throttle tube kit. Cycleworks should either include a small, cheap key, or just install the spigots while they're jetting the carbs.

3) Better instructions with some pictures and/or a better drawing than the one that's included. The instructions in the kit did include all the steps necessary for the install, but just weren't that great. For $900+, when you're telling me I need to cut out the vertical support in the air box, I'd like a picture highlighting exactly what I should be cutting out.

Beside that, everything else was positive. The only thing that really sucks is that I CAN'T RIDE RIGHT NOW! It's 12 degrees outside today and the whole left side of my motor is torn apart.

I was real glad I had Alex there to help, I would have needed to be an Octopus if he wasn't there.

Labels:

diy,

ducati,

ducati monster,

keihin,

M900,

motorcycles

Tuesday, January 7, 2014

Finished machining

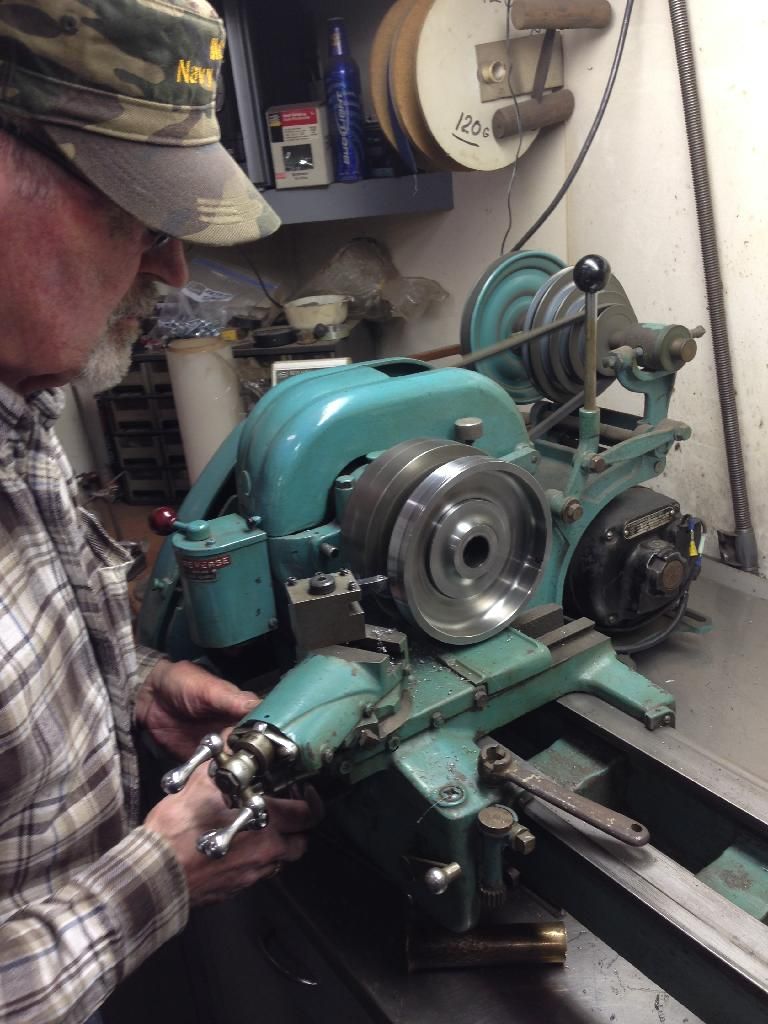

Last night Earl and I finished up the machining on the Duc flywheel, getting its weight down to 2.65 lbs. As a fellow user of the ducatimonsterforum.org encouraged me to find out, I calculate that because I bought Earl a 30 pack of Busch Light for his services, my cost was 17 beers per pound lost. Flywheel going back in the bike tonight!

Friday, January 3, 2014

Lightening the Flywheel

One of the winter projects I really wanted to get done this year was to lighten the stock flywheel in the Ducati. I've got Earl, who is a wizard, so I figured, why not?

BROKEN ALTERNATOR COVER:

So I go to work on removing the alternator cover, from the looks of things, I'm fairly certain this hadn't been done since the bike came off the production line. It took a puller from Ace to pop the cover off. Unfortunately, when I finally had the cover in my hand and looked at the back side of it I saw this:

If you look in the middle you can see a "ring" that is just floating there as well as a loose c-clip, can't be good.

Come to find out, that loose ring is actually a retaining lip that has cracked off the cover itself. Basically it's there to keep the bearing from walking down the shaft. Son of a bitch. I believe what happened is that the puller needed too many turns to pop the cover off, and when it finally popped, the end of the puller impacted the bearing itself, cracking the lip behind it. I should have been tapping the cover to loosen it up as I was twisting the puller bolt. Here's some pictures of the broken parts:

After talking with a few people on forums and through e-mail threads, I made the decision that it's really not that important of a lip, because the earlier models didn't even have it, AND because it took some really firm whacks with a drift and dead-blow hammer to get that bearing seated back to where it needs to be.

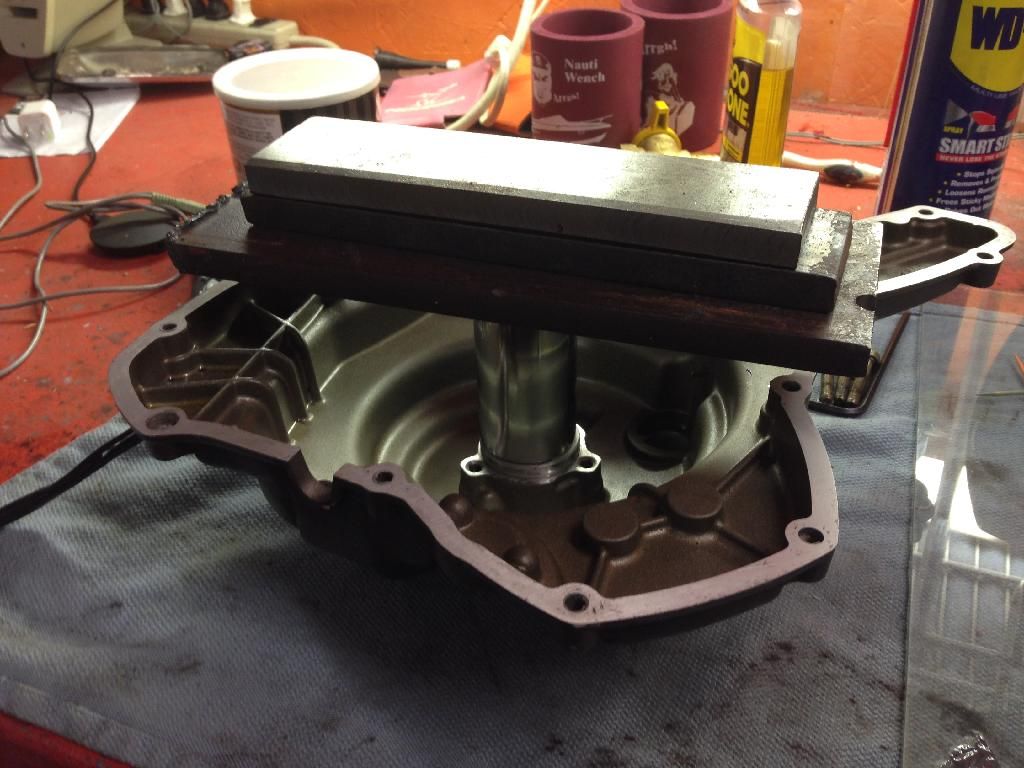

So, I decided to clean up the area and turn to trusty JB-Weld. I know, not the best option in the world, but sure enough, it worked. Once I cleaned the area thoroughly and spread the JB over the retaining lip, I pressed it down into place and used a socket of the same diameter with some steel weight on it to apply pressure over night:

The next day it was very firmly in place and I was able to snap the c-clip back under the lip no problem. The bearing spins freely and all looks to be good. I seriously doubt this will ever cause any problems.

BACK TO THE FLYWHEEL:

From there, disassembly was fairly easy. Once I removed the flywheel and all the parts from it, I headed over to Earl's to let him work his magic.

4.5 lbs stock:

You can see the ball of shavings developing in this picture, only about halfway through:

And the after weight, 3.3 lbs:

I kind of would have liked to be below 3, so I may look for some more material to safely take off. However, I'll be happy with anything. The bike should rev up and engine-break quicker, making for a more exciting, and responsive ride. Should also make the bike slightly more "flickable." Now to reassemble.

Ducati Monster Paddock Lift

So I really wanted a paddock-style lift stand like the one Bursig and Moto-Mfg make, but couldn't justify spending the money. I work at a company where I can get steel pretty cheap, so I decided to have a go at making one myself. Here are links to the two brands mentioned above. If you're a beginning fabricator, like myself, you might just consider buying one from them. This was a fun project, but it took quite a long time to get it just right.

http://www.bursigusa.com

http://www.motomfg.com/MotoMfg_paddock_stand_Ducati_p/ps-1.htm

Really the biggest complication I had to get past was modifying the motor mount bolt. These lifts work by installing a semi-permanent lift point onto a motor mount bolt. Unfortunately on the M900's, the bolt doesn't stick out of the frame enough to thread something extra on to. I learned that bolts from later Monsters would give me the length I needed, but they had a different thread and diameter. So, I picked two of them up for something like $12 and had my trusty retired-machinist, Earl, turn one down in his lathe and we then re-threaded the end to fit my bike. I now had the length i needed:

After that, I gave him some solid bar stock and he went to work machining my lift point, that is now threaded onto the bike itself:

The last piece of machining he had to do was the plate that the lift pin is mounted in:

From there I was able to cut, bend, weld, and paint my way to the finished product. I ran into some snags, mostly from underestimating the force that 400~lbs was going to have on the lifting components. But now I have a working version. It doesn't work as smoothly as some of the mass-produced ones, but I'm also not using it in a racing environment. I'll just be using it for working on the suspension, cleaning the wheels, and moving the bike around the garage into tight corners.

Labels:

bursig,

diy,

ducati,

ducati monster,

lift,

moto-mfg,

paddock stand

Ducati Monster was Finished...

... for about 3 months while I was letting this blog die. I'm having a real hard time committing to putting content on here.

Anyway, below are some pictures from the finishing process as well as the end result. I'm also working on some other projects on the Duc, and haven't had the money or time to get back to work on the Virago.

Anyway, below are some pictures from the finishing process as well as the end result. I'm also working on some other projects on the Duc, and haven't had the money or time to get back to work on the Virago.

Subscribe to:

Comments (Atom)