One of the winter projects I really wanted to get done this year was to lighten the stock flywheel in the Ducati. I've got Earl, who is a wizard, so I figured, why not?

BROKEN ALTERNATOR COVER:

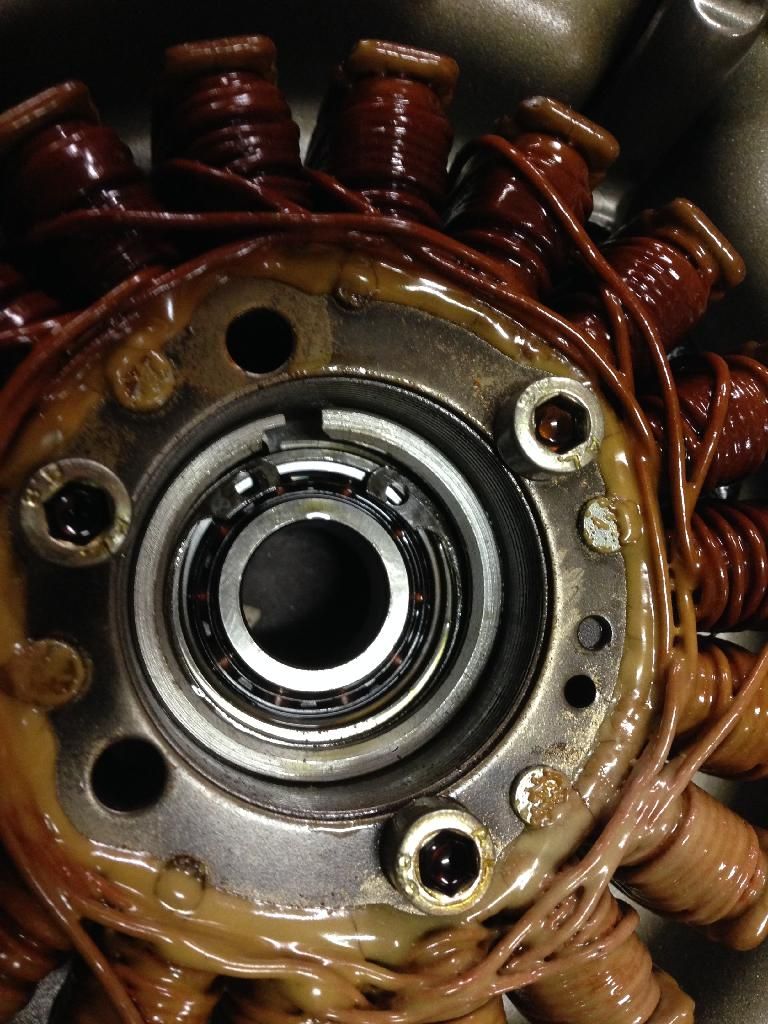

So I go to work on removing the alternator cover, from the looks of things, I'm fairly certain this hadn't been done since the bike came off the production line. It took a puller from Ace to pop the cover off. Unfortunately, when I finally had the cover in my hand and looked at the back side of it I saw this:

If you look in the middle you can see a "ring" that is just floating there as well as a loose c-clip, can't be good.

Come to find out, that loose ring is actually a retaining lip that has cracked off the cover itself. Basically it's there to keep the bearing from walking down the shaft. Son of a bitch. I believe what happened is that the puller needed too many turns to pop the cover off, and when it finally popped, the end of the puller impacted the bearing itself, cracking the lip behind it. I should have been tapping the cover to loosen it up as I was twisting the puller bolt. Here's some pictures of the broken parts:

After talking with a few people on forums and through e-mail threads, I made the decision that it's really not that important of a lip, because the earlier models didn't even have it, AND because it took some really firm whacks with a drift and dead-blow hammer to get that bearing seated back to where it needs to be.

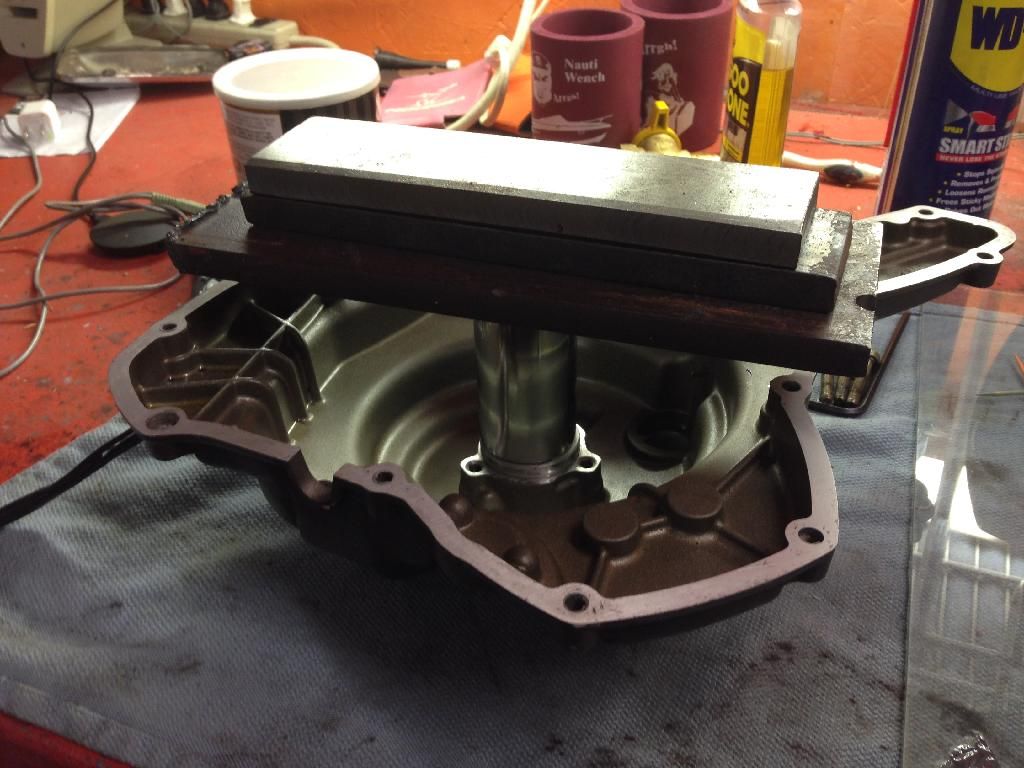

So, I decided to clean up the area and turn to trusty JB-Weld. I know, not the best option in the world, but sure enough, it worked. Once I cleaned the area thoroughly and spread the JB over the retaining lip, I pressed it down into place and used a socket of the same diameter with some steel weight on it to apply pressure over night:

The next day it was very firmly in place and I was able to snap the c-clip back under the lip no problem. The bearing spins freely and all looks to be good. I seriously doubt this will ever cause any problems.

BACK TO THE FLYWHEEL:

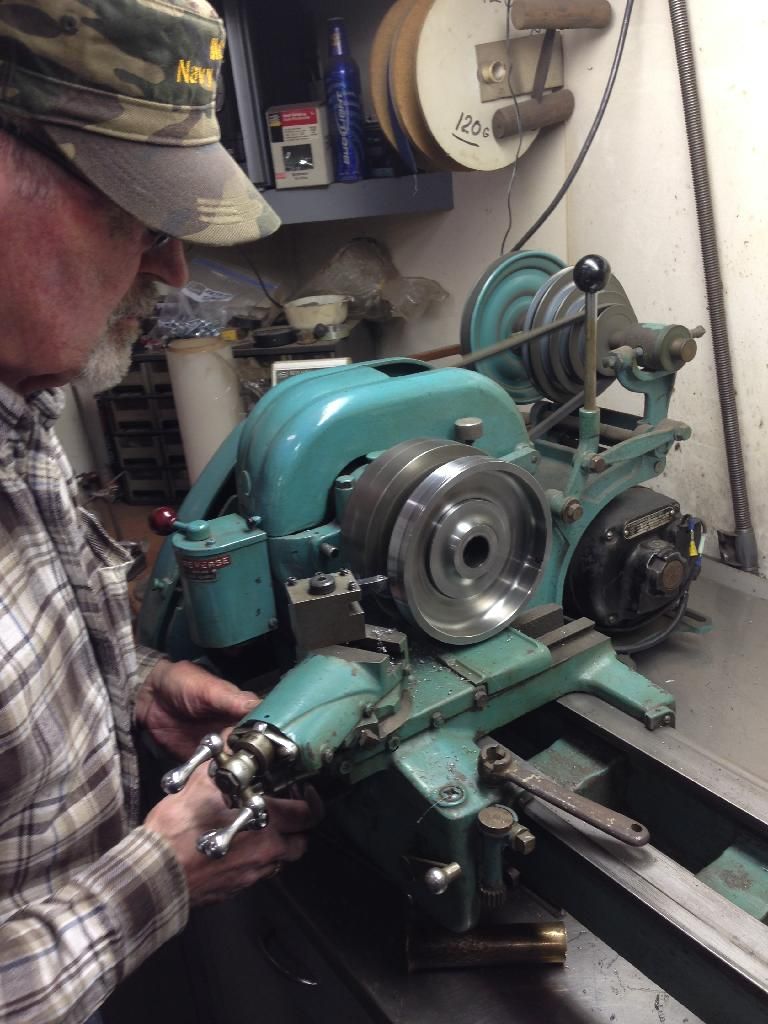

From there, disassembly was fairly easy. Once I removed the flywheel and all the parts from it, I headed over to Earl's to let him work his magic.

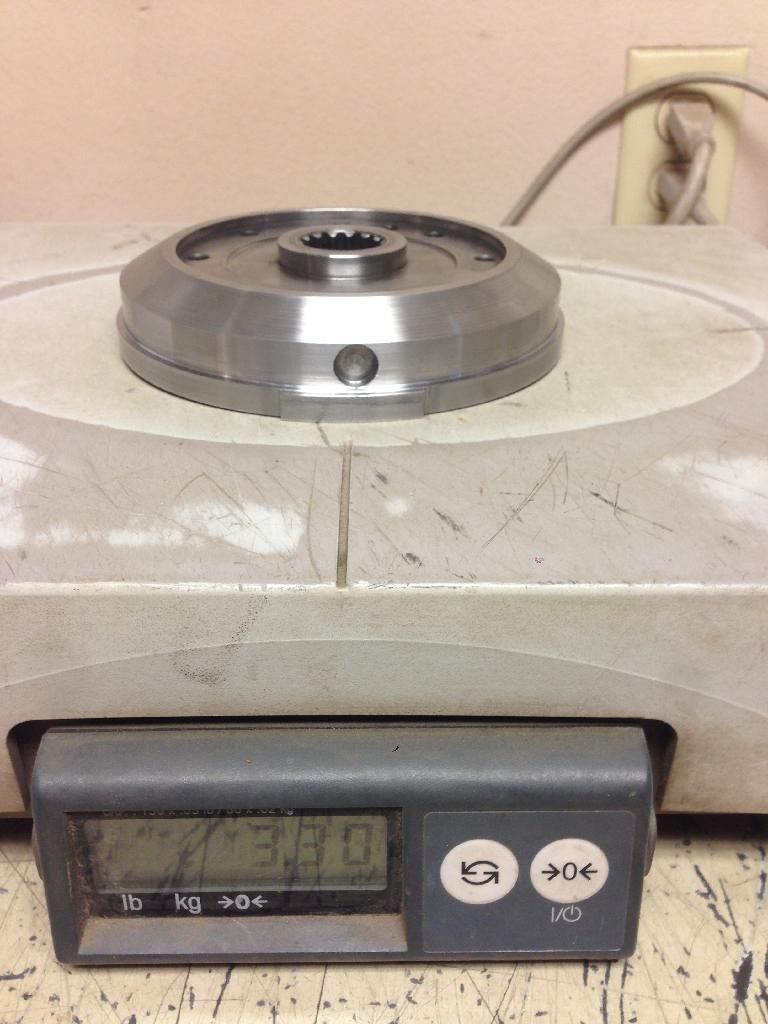

4.5 lbs stock:

You can see the ball of shavings developing in this picture, only about halfway through:

And the after weight, 3.3 lbs:

I kind of would have liked to be below 3, so I may look for some more material to safely take off. However, I'll be happy with anything. The bike should rev up and engine-break quicker, making for a more exciting, and responsive ride. Should also make the bike slightly more "flickable." Now to reassemble.