I decided that the silver triple trees and handlebar risers were just too out of place with the direction my bike has gone. And, since I have a bunch of time on my hands waiting for China to fix their screw up and for the snow to melt, I decided to tear the front end off and paint them black. Turned out great.

Dement Ave.

Custom Bikes and Boats

Friday, February 7, 2014

Painted Triple Trees

I decided that the silver triple trees and handlebar risers were just too out of place with the direction my bike has gone. And, since I have a bunch of time on my hands waiting for China to fix their screw up and for the snow to melt, I decided to tear the front end off and paint them black. Turned out great.

China blows. New Reservoir.

I finally got around to changing out my brake and clutch reservoirs to something more aesthetically pleasing. I turned to China for some cheap, simple, black reservoirs. Of course... they send me one black and one gold. One of those moments where you think, "You had one job!"

So now I get to wait weeks and weeks for them to get their shit together and send me a new one.

Here's some previous shots as well as the one that I got installed:

So now I get to wait weeks and weeks for them to get their shit together and send me a new one.

Here's some previous shots as well as the one that I got installed:

Wednesday, January 29, 2014

Homemade Fork Spring Compressor

The last tool I made was just a "U" of flimsy steel, didn't hold up very long and was hard to work with. I happened to look inside one of the scrap steel bins at work and saw a 4 inch long piece of pipe. I thought it would be the perfect size for making a new compressing tool. I took it home and threw it in the cutoff saw to take make a 3/4" width ring. I then ground off all the shavings and sharp edges, and threw it in the drill press. My bit couldn't reach the other side of the ring so I took it out of the vise, and marked where the hole on the other side would have to be.

After drilling both holes to the correct tap diameter, I tapped them for the 3/8" bolts that I would be threading into them. Since the bolts meet in the middle, I think it should work just fine, haven't had an opportunity to use it yet. Painted it gloss black and I'm done!

After drilling both holes to the correct tap diameter, I tapped them for the 3/8" bolts that I would be threading into them. Since the bolts meet in the middle, I think it should work just fine, haven't had an opportunity to use it yet. Painted it gloss black and I'm done!

Friday, January 24, 2014

Reassembly Updates

So I finally got all the parts in that I need to repair the damaged timing side of the motor: Idler gear, reduction pin, flywheel gear, and starter clutch. I also decided to just replace the entire side cover so I didn't have to worry about that Bondo'ed retaining lip. A fellow DMF member offered me a screaming price on the cover so it was hard to pass up. All in all, after selling that nice Nichols flywheel that I couldn't use, I came out ridiculously cheap for the parts. All included, I spent $59 on the replacement parts.

Earl and I took some more material off the flywheel and drilled a balancing hole, shown here:

After getting the new side cover in the mail, I realized I wouldn't be okay with having two side covers of different color, so I decided to prep and paint them. While I was cleaning the clutch-side cover, I ran my index finger along a very sharp lip, and got insta-blood:

Truly blood, sweat, and tears poured into getting this thing ready.

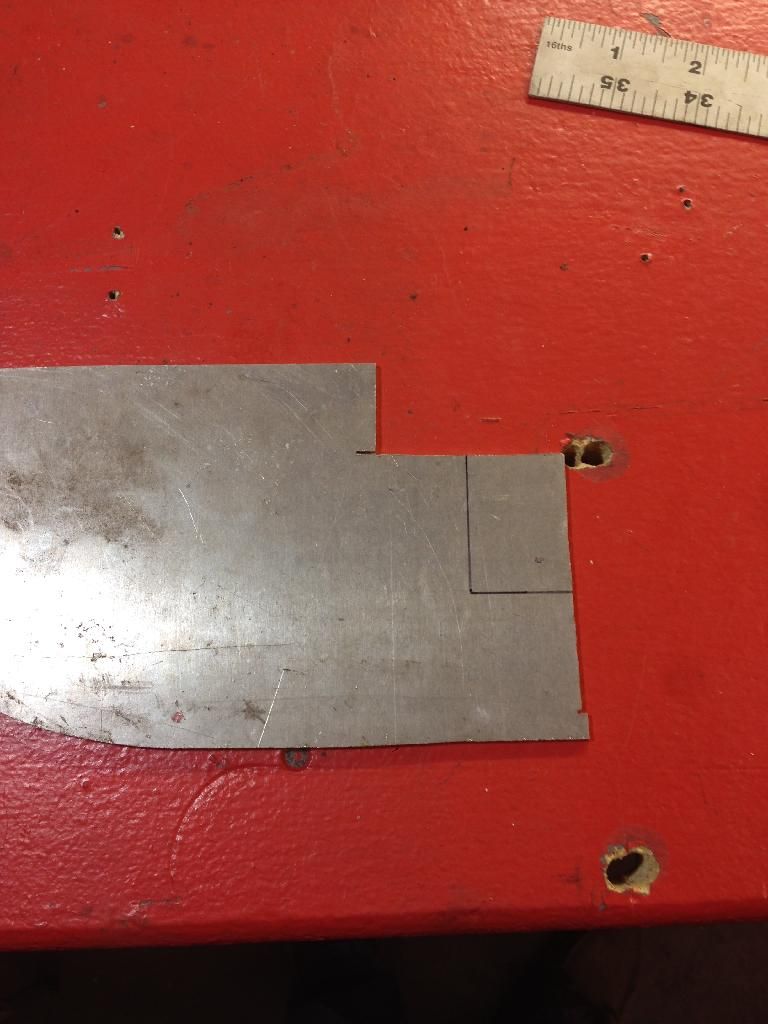

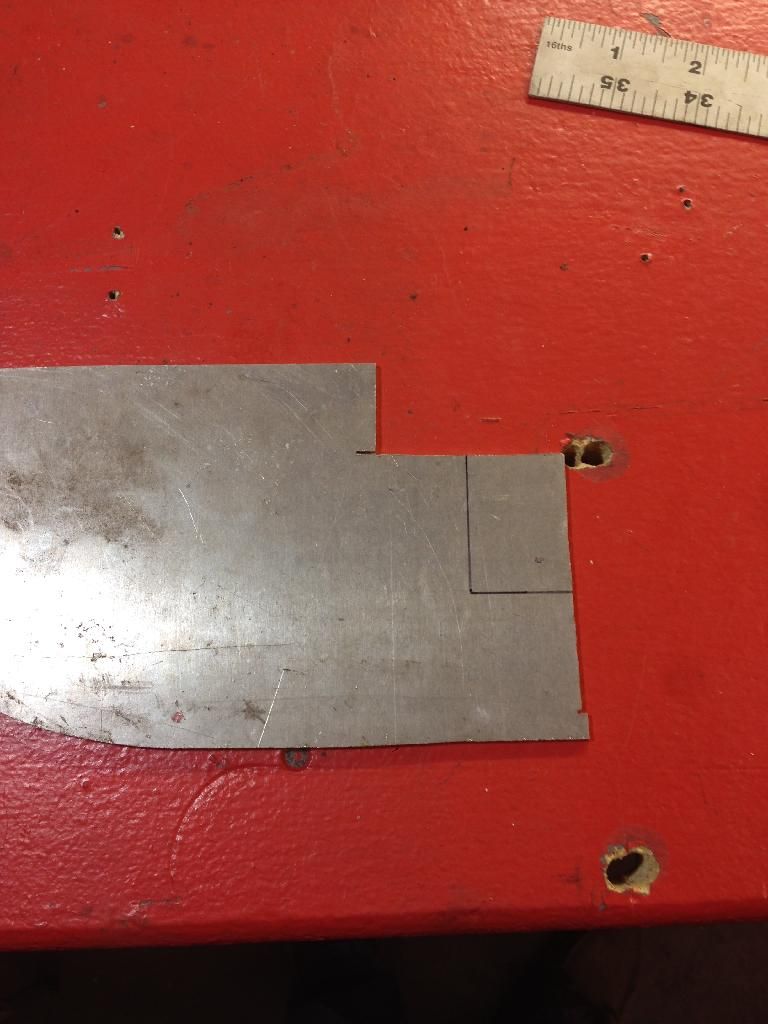

Before I started painting I needed to make a small cover and gasket for a sensor hole in the new cover (my old one didn't have the hole). Started off with a sheet of aluminum, cut out a rectangle, then used my Dremel, grinding wheel, and file to shape the rest of it. A piece was cut out of stock gasket material in the shape of the cover.

Here are the covers before paint, showing why I wanted to paint in the first place:

Here they are after the first, light coat of VHT engine paint. Yes, I used some duct tape for masking tape. I made the mistake of buying Ace Hardware brand painters tape and it was absolutely terrible. Had to make due with what I had at that point:

Three coats in:

After 30 minutes of curing at 200 degrees in the oven... I don't think Laura was too happy about motorcycle parts baking in her kitchen...

Finally a picture on the bike. I'm still waiting on the gasket for the right side cover to come in:

Earl and I took some more material off the flywheel and drilled a balancing hole, shown here:

After getting the new side cover in the mail, I realized I wouldn't be okay with having two side covers of different color, so I decided to prep and paint them. While I was cleaning the clutch-side cover, I ran my index finger along a very sharp lip, and got insta-blood:

Truly blood, sweat, and tears poured into getting this thing ready.

Before I started painting I needed to make a small cover and gasket for a sensor hole in the new cover (my old one didn't have the hole). Started off with a sheet of aluminum, cut out a rectangle, then used my Dremel, grinding wheel, and file to shape the rest of it. A piece was cut out of stock gasket material in the shape of the cover.

Here are the covers before paint, showing why I wanted to paint in the first place:

Here they are after the first, light coat of VHT engine paint. Yes, I used some duct tape for masking tape. I made the mistake of buying Ace Hardware brand painters tape and it was absolutely terrible. Had to make due with what I had at that point:

Three coats in:

After 30 minutes of curing at 200 degrees in the oven... I don't think Laura was too happy about motorcycle parts baking in her kitchen...

Finally a picture on the bike. I'm still waiting on the gasket for the right side cover to come in:

Thursday, January 16, 2014

Big Problems

On Sunday, Illinois weather reached a balmy 42 degrees, making about a 70 degree swing from the week before. So, Scott and I decided we had to go for a ride in the beautiful January weather.

The Duc ran great for about 10 minutes, I was VERY happy with the effects of the lightened flywheel. Nice, snappy throttle response. Scott and I get to a gas station to re-fuel, shut the bike down, try to leave, no go. The starter's trying to spin but nothing will happen.

I immediately suspect the ring that had cracked off on the inside of the cover before, and we get the bike back to my garage on a trailer (luckily we were only 1 mile from my house).

Start tearing into the bike and find that not only is the flywheel reluctant to come off of the shaft, but the idler gear is stuck in place as well.

Finally, with a puller, I am able to separate the flywheel from the starter driven gear and find that one of the sprags in the starter clutch is turned 90 degrees:

That sprag turned like that was preventing the "clutch" action and was spinning the gear at the same speed as the flywheel... and motor. Because that gear was spinning it picked up some serious scarring:

Since it was spinning, the idler and starter gears were spinning too. The idler gear only spins on a pin, no bearing, so it must have gotten VERY hot from the friction, then when I shut the motor down it seized itself in place. It took some serious turns on a puller to get the idler gear to come free of the pin:

Now my motor is sitting like this while I wait for parts:

I think there's really only two possible causes of this problem. Either the flywheel is so out of balance it broke the clutch, or the clutch got damaged/installed wrong while I had it out to lighten the flywheel. Either way, I'm going to make sure the flywheel is balanced, and a new sprag is on it's way so the problem should be resolved.

My next issue is that the idler reduction pin is stuck in the case. It has some minor marring on the end of it, which makes me want to remove and replace. However, it's really really stuck. So, I'm halfway considering just lightly sanding it until it's smooth again. Theoretically the idler gear only spins for a short while, and doesn't ever get all that hot. Still deliberating.

Keihin Carbs

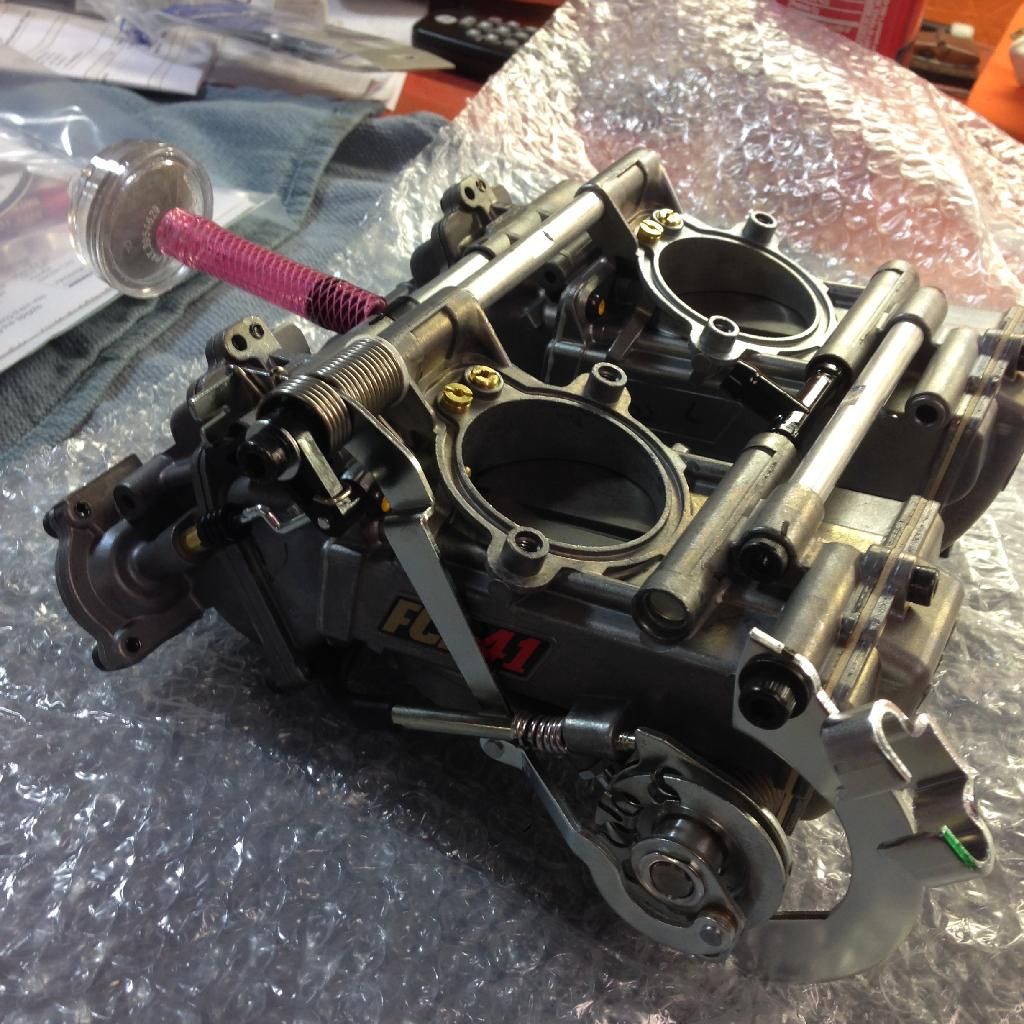

The mailman made me happy yesterday, when I received my brand-new Keihin FCR 41's from Ca-Cycleworks. These bad boys are one of the final pieces I think I'll be able to justify doing to the Monster, aside from suspension upgrades.

As far as installation goes, it was mostly fine. I think for $900+ there are three things that should be included in the kit you receive:

1) New rubber flanges for the air box. The OEM ones are a pain to stretch over the FCR's, AND I had to go to the hardware store to buy longer bolts to allow the clamps to reach all the way around the carb opening.

2) A ball-end 5mm allen key. In the instructions they say you need one. I have non-ball type keys and really didn't feel like buying the ball-end just for the four small bolts you have to use it on. So I ended up grinding one of mine down and doing it that way. Motion Pro includes a hex key in their throttle tube kit. Cycleworks should either include a small, cheap key, or just install the spigots while they're jetting the carbs.

3) Better instructions with some pictures and/or a better drawing than the one that's included. The instructions in the kit did include all the steps necessary for the install, but just weren't that great. For $900+, when you're telling me I need to cut out the vertical support in the air box, I'd like a picture highlighting exactly what I should be cutting out.

Beside that, everything else was positive. The only thing that really sucks is that I CAN'T RIDE RIGHT NOW! It's 12 degrees outside today and the whole left side of my motor is torn apart.

I was real glad I had Alex there to help, I would have needed to be an Octopus if he wasn't there.

As far as installation goes, it was mostly fine. I think for $900+ there are three things that should be included in the kit you receive:

1) New rubber flanges for the air box. The OEM ones are a pain to stretch over the FCR's, AND I had to go to the hardware store to buy longer bolts to allow the clamps to reach all the way around the carb opening.

2) A ball-end 5mm allen key. In the instructions they say you need one. I have non-ball type keys and really didn't feel like buying the ball-end just for the four small bolts you have to use it on. So I ended up grinding one of mine down and doing it that way. Motion Pro includes a hex key in their throttle tube kit. Cycleworks should either include a small, cheap key, or just install the spigots while they're jetting the carbs.

3) Better instructions with some pictures and/or a better drawing than the one that's included. The instructions in the kit did include all the steps necessary for the install, but just weren't that great. For $900+, when you're telling me I need to cut out the vertical support in the air box, I'd like a picture highlighting exactly what I should be cutting out.

Beside that, everything else was positive. The only thing that really sucks is that I CAN'T RIDE RIGHT NOW! It's 12 degrees outside today and the whole left side of my motor is torn apart.

I was real glad I had Alex there to help, I would have needed to be an Octopus if he wasn't there.

Labels:

diy,

ducati,

ducati monster,

keihin,

M900,

motorcycles

Subscribe to:

Comments (Atom)